E-Type Eco Power-Saving

Under the wave of Industry 4.0, various industries are investing in automation to improve production speed, flexibility, and cost-effectiveness, but another major problem has arisen!

In the automation process, regardless of the compressed air driven by pneumatic or the power consumption of electric drive, it will cause a lot of energy consumption.

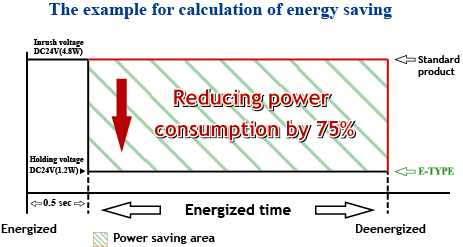

SHAKO launched the E-Type series products, which not only reduce the power consumption of the solenoid valve by more than 75% but also reduce the temperature of coil on solenoid valve to extend the service life of solenoid valve.

E-TYPE Eco Power-Saving Solenoid Valve

■ Features

- Save power by reducing current consumption.

- Reduce the temperature of coil on solenoid valve to improve performance and extend service life of solenoid valve besides save power.

■ Operating Principle

When the solenoid valve is energized, inrush voltage is first applied to switch the valve. After the valve switching is completed, the solenoid valve at this time only needs a small current (and power) to maintain the current state of the valve, which is called holding current, SHAKO utilizes this characteristic to make "Power-saving" solenoid valves.

Generally, pulse-width modulation (PWM) is a common way for power saving control, but power saving efficiency by this way is limited. Therefore, SHAKO adopts "smart IC chip + special process" to directly reduce current for power saving control.

■ Test condition:

Coil: 24VDC (4.8W), Operating time: 12 hrs /day, 22 days/month

- Coil with standard connector/pc :4.8W *12 hrs * 22 days =1267.2W/month

- Coil with E-type connector/pc:1.2W * 12 hrs * 22 days =316.8W/month

Monthly Save: 1267.2W - 316.8W = 950.4W/pc